1. Product introduction

Intelligent pressure transmitter is a new type of intelligent instrument jointly developed by our company using domestic multi-party technical forces. The instrument uses microprocessor technology for temperature compensation and nonlinear compensation, thereby greatly improving the measurement accuracy of the instrument, improving temperature characteristics, expanding the range ratio, and adding intelligent configuration functions, further satisfying the high reliability and high stability of industrial field instruments. Require. The key components and parts are imported, and the whole machine leaves the factory after strict testing. It has the characteristics of advanced design principle, reliable product quality, complete varieties and specifications, and easy installation and use.

2. Features and Specifications of Intelligent Transmitter 2-1 Product Features

■The instrument can be configured in real time during the operation of the instrument, such as modifying the range, monitoring variables, etc.

■The pressure signal can be intelligently linearized to ensure accurate and reliable measurement data.

■There are reverse protection circuits and current limiting circuits on the circuit board to avoid accidental damage to the circuit as much as possible.

■The parameters stored in EPROM after configuration can remain unchanged.

■High precision and high reliability.

■Solid components, plug-in electronic circuit boards, strong and anti-vibration.

■Explosion-proof structure, all-weather use.

■Span, zero point and damping are continuously adjustable on site.

2-2 Functional Specifications

■Measuring range:

Rated range | 0-0.125 ~ 1.6KPa | 0-1.3~8KPa | 0-6.2~40KPa | 0-31.1~250KPa |

Single-ended static pressure upper limit | 6Mpa | 8Mpa | 10Mpa | 10Mpa |

Rated range | 0-0.117~1MPa | 0-0.345~2.5MPa |

|

|

Single-ended static pressure upper limit | 10Mpa | 13Mpa |

|

|

■Zero point and span:

It can be adjusted with the range and zero buttons of the machine, or remotely with the HART handheld smart terminal. Positive and negative transfer of zero point:

When the zero point is negatively shifted, the lower limit of the range must be greater than or equal to -URL; when the zero point is positively shifted, the upper limit of the range must be less than or equal to +URL. The inspection range must be greater than or equal to the lower limit of the range.

2-3 Performance Specifications

■Output signal: DC4-20mA+HART protocol

■Output method: Linear output

Square root output (remotely adjustable via configuration software)

■Damping time constant: The time constant is adjustable in increments of 0.1 seconds, from as small as 32 seconds, such as damping

When the time is 0, the default is 0.1.

■Ambient temperature limit: ordinary type -40 to 85 ℃, LCD head 20 to 70 ℃

■Process temperature limit 40 to 104°C

■Storage temperature limit 40 to 85 ℃

■Ambient humidity 0-95% relative humidity

■Volume change: less than 0.01in3 (4px)3 (zero reference calibration range, under reference conditions, silicone oil filling, 316L stainless steel isolation diaphragm)

■ Accuracy: Turndown ratio<5:1:≤±0.1 % FS

Turndown ratio≥5:1:≤±0.25 % FS

■Stability: 6 months, ±0.5%URL

■Ambient temperature affects 29 to 85 ℃

Zero error: 0.5%URL/56℃

Overall error: (0.5%URL+0.2% calibration range) /56℃

■Vibration effect: On any axis, the vibration effect is 0.2%URL/g at 200Hz

■Power supply range: 12~36VDC

■Intrinsically safe explosion-proof: Ex ia IIC T6 Ga

Note: Intrinsic safety must be powered by a safety barrier or an intrinsically safe power supply

■Influence of installation position: The zero drift is at most ±0.25KPa. All zero drifts are available

Corrected; no effect on the range.

■Load Effect: No load effect unless there is a change in the power supply voltage.

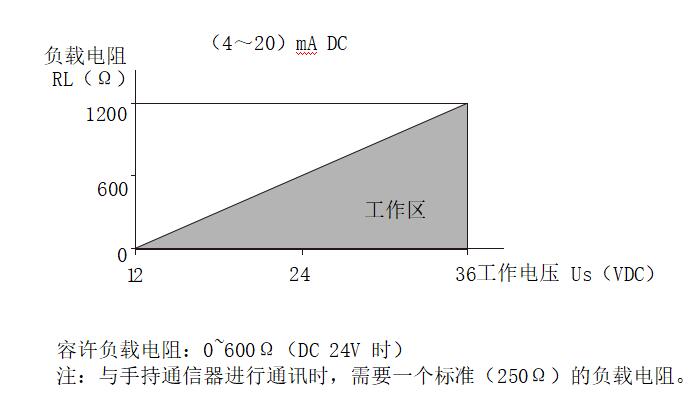

■Load characteristics: Current type load≤{(Us-12)÷0.02(Us=supply voltage)}Ω

2-4 Product Application

■Used with the device to measure the flow of gas, steam and liquid (volume flow or mass flow).

■ Level, volume and mass measurement of liquids.

■ Differential pressure monitoring.

3. Transmitter structure material

■Isolation diaphragm: 316L stainless steel.

■Vent/drain valve: 316L stainless steel.

■Flanges and joints: 316L stainless steel.

■"O" ring: Fluorocarbon plus nitrile rubber.

■Filling fluid: Silicone oil.

■Bolt: 316 stainless steel/20# steel.

■Electronic housing: Low copper alloy aluminum.

Fourth, the working principle of the transmitter

The intelligent circuit board adopts advanced integrated circuit and SMT technology, and concentrates the conversion circuit and processing circuit on one circuit board.

The microprocessor of the transmitter controls the work of A/D and D/A conversion modules, and also completes digital communication and self-diagnosis functions. When working, the microprocessor controls the A/D conversion module to sample and convert the analog signal from the sensitive element and convert it into a digital signal. The microprocessor processes the digital signal, including signal linearization, temperature compensation, engineering unit conversion, etc. The microprocessor can also perform sensor characterization, range, damping time, and other functions. EPROM stores all configuration and fine-tuning parameters. Since the memory is non-volatile, the stored parameters will not be lost after power failure.

5. Product pictures